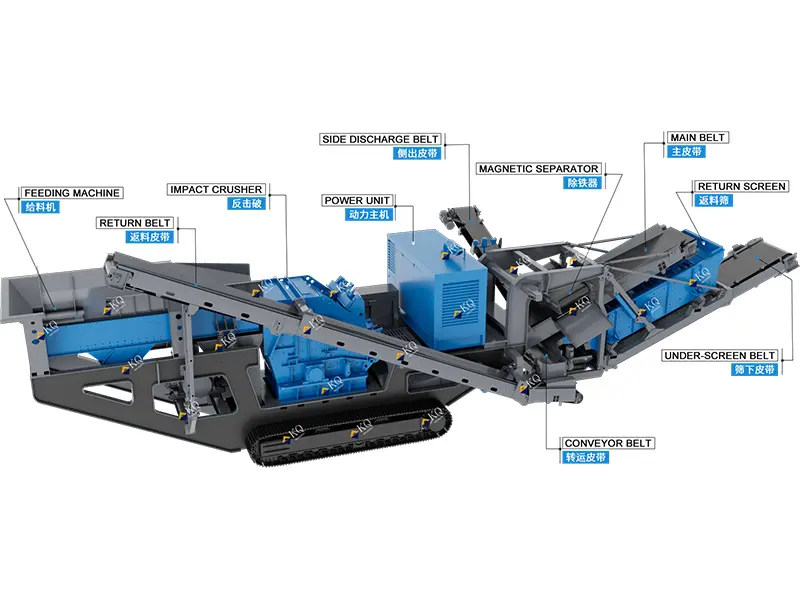

The tracked mobile impact crusher is specifically designed for efficient crushing and complex terrain operations. Equipped with a fully hydraulic tracked undercarriage and a hydraulic impact crusher, it delivers high crushing capacity, low operating costs, high versatility, and adjustable uniform particle size. It can be paired with a vibrating screen for integrated crushing and screening operations, or combined with tracked cone crushing stations and other equipment.

|  |

The Track-Mounted Impact Crushing Plant, With Its Unique Design, Is The Preferred Solution For Sand And Gravel Aggregate Production And Construction Waste Recycling.

🟠1. High-Efficiency Counterattack, Excellent Particle Shape:

The large-caliber impact crusher features a wide feed opening design, capable of processing large-sized materials while achieving high throughput. Material fragmentation is accomplished through high-speed impact, resulting in finished products with a three-dimensional, uniform particle shape. It is an ideal choice for producing high-quality concrete aggregates and asphalt mixes.

🟠2.Integrated Intelligence, Wide Application:

Featuring integrated feeding, crushing, screening, and iron removal functions, along with hydraulic discharge adjustment and a variable-speed main unit, this system is particularly suited for small-to-medium quarries, on-site processing of urban construction waste, and temporary aggregate needs for various projects. It significantly reduces overall operating costs (by up to 30%).

🟠3.Exceptional Maneuverability, Breaking Through On Demand:

Its tracked chassis delivers formidable off-road capability, effortlessly traversing rugged terrain, muddy surfaces, and uneven job sites. Combined with 35° gradeability and zero-turn capability, it ensures “wherever the material is, the equipment goes.” With a single press of a button, it can penetrate complex terrains like mines and construction sites, even operating directly beside raw material piles—eliminating costly and time-consuming material transport.

🟠4.Rapid Relocation, Energy-Efficient And Eco-Friendly:

No dismantling or reassembly required upon project completion or site change. Deployable at new locations within hours, significantly boosting equipment utilization and drastically shortening project timelines.

Equipped with a dual-power system featuring intelligent fuel-electric switching, achieving up to 25% fuel savings. Pure electric mode meets urban environmental compliance requirements.

|  |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Device/Model | PLF150RS | PLF250RS | PLF350RS |

Feeders | |||

Bin Volume(m³) | 4 | 6 | 6 |

Feeder Model | FD1030 | FD1240 | FD1245 |

Feeder Power(KW) | 2.2*2 | 3.7*2 | 5.5*2 |

Maximum Feeding Particle Size(mm) | 500 | 750 | 750 |

Crusher | |||

Device/Model | PLF150RS | PLF250RS | PLF350RS |

Crusher Power(KW) | 160 | 250 | 315 |

Processing Capacity(t/h) | 80-200 | 100-400 | 150-500 |

Return Material Sieve | |||

Device/Model | SX1230 | SX1540 | SX1745 |

Number Of Screen Layers | 1(2) | 1(2) | 1(2) |

Belt Conveyor | |||

Main Belt Conveyor | B800 | B1200 | B1200 |

Belt Conveyor Under Screen | B800 | B1200 | B1200 |

Material Return Belt Conveyor | B500 | B500 | B500 |

Drive Mode | Motor Reducer | Motor Reducer | Motor Reducer |

Machine Power(KW) | 215.4 | 317.4 | 382.4 |

Power System(KW) | Cummins 330 | Cummins 560 | Mains power |